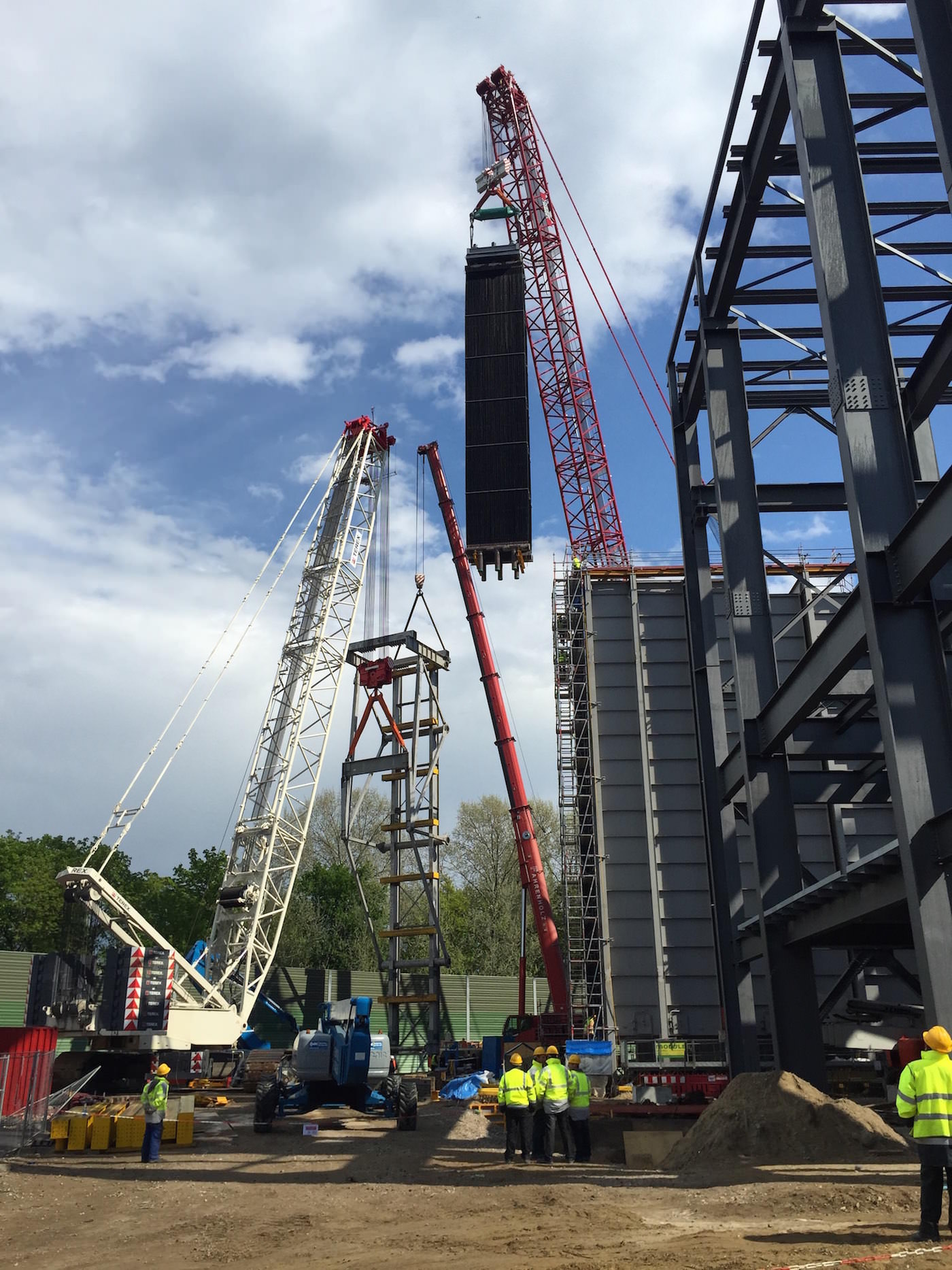

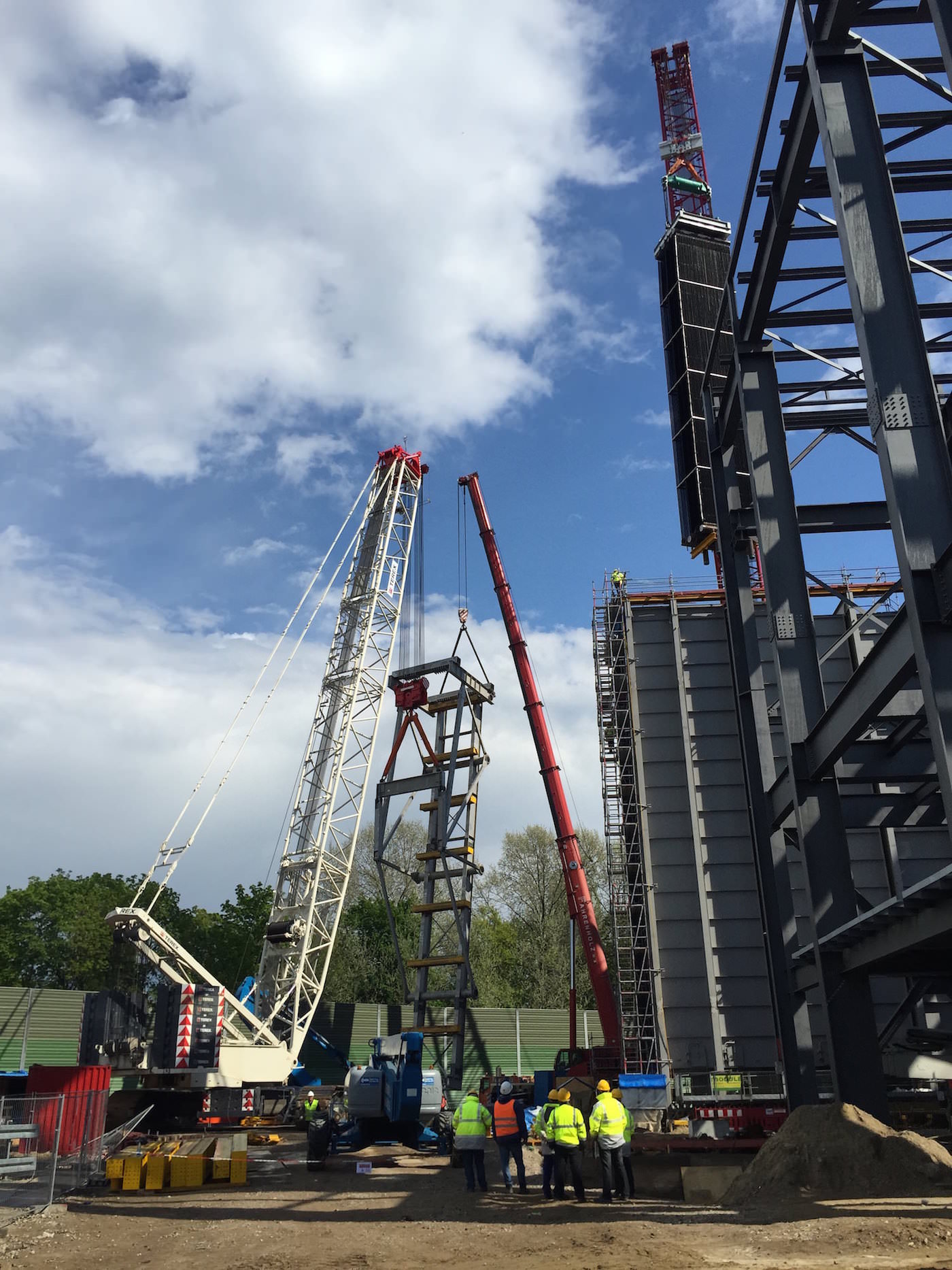

Uprighting and installation of 10x 250 tons HRSG modules

What was the challenge?

Our client, a global energy supplier, inquired us two years before physical execution in order to plan the entire operation. Since the resource space is limited due to an existing plant in operation, surrounded civil housing, one access road to site and one partially 3m wide circle road on site our client had the problem how to deliver from a port, upright and install each of the ten HRSG modules into the HRSG structure.

What did our client do about this?

Our client, a global energy supplier, inquired us two years before physical execution in order to plan the entire operation. Since the resource space is limited due to an existing plant in operation, surrounded civil housing, one access road to site and one partially 3m wide circle road on site our client had the problem how to deliver from a port, upright and install each of the ten HRSG modules into the HRSG structure.

- Tasks

At first we assessed the HRSG manufacturer’s operations manuals and drawings. The aforementioned concept encompassed to:

Horizontally lift each module with a horizontal lifting device from an SPMT trailer into an uprighting frame. The uprighting frame itself had a deadweight of more than 40 tons and a length of 30m.

Upright each module inside the uprighting frame with three cranes simultaneously, lift and install each module into the HRSG structure with a height of 27m.

- What did we do?

- Calculated load distributions of combination of module and uprighting frame for each crane

- Defined the minimum capacities of each crane for the “three crane lift” and their setups on site: These were

- 600 tons crawler crane, CC2800-1, 72m main boom, Superlift and Superlift counterweight, Vario-SL necessary

- 400 tons crawler crane, CC2400, 42m main boom

- 250 tons all terrain crane, AC250, 42m main boom

- Defined the necessary rigging material

- Defined the applicable SPMT trailer length and capacity: 18 axles of Scheuerle SPMT + 1 PPU

- Defined the necessary cherry pickers

- Defined the minimum crane capacity and setup for discharging the modules in the port. This model was:

- LR 1400-2, 42m main boom, Superlift and Superlift counterweight

- Assessed and framed logistics:

- Assessed roads to site and the overall logistics situation that was applicable

- Assessed the total amount of transports that will enter and leave site frequently for crane mobilization and demobilization: 72

- Developed a logistics scheduling and procedure

- Assessed and framed necessary HSE criteria to be met

- What did we deliver?

- Created a multi-langualge operations manual for logistics and liftings that explained and illustrated each of the relevant operations and preconditions. That documentation entailed all relevant technical specifiations ready of stress calculation for official approval and served our client as applicable foundation for inquiring the incorporated services.

- Agreed with client’s proof engineering, especially in terms of ground bearing pressures in relation to vertical and horizontal pressures affecting subsurface piling

- Created a isometric three dimensional simulation

- Presented the entire concept twice to our client’s client as ordered by our client

- Coordination and supervision of the entire process during execution including all liftings

- Did it work?

Worked out without any technical or HSE-relevant or commercial incident. There was not a single negeative deviation from the planning documents that we elaborated. In contrast, we assumed one module lift each day. In fact, we were partially able to lift two modules each day.

- Measurable benefit for our client?

Yes indeed. Through sustainable planning there was no deviation. Since we lifted faster than assumed we reduced downtime and costs dramatically. All stakeholders by means of the project’s particapants and especially our client’s client were totally satisfied. Especially three dimensional simulation of the limited space available for crane mobilization and demobilization as well the uprighting and lifting proactively created a sustainble impression at our client’s client. In other words, through our work our client was holistically exempted from any potential obstacles and problems.